Hey, I'm new here but have always loved cars. This project will be for an Audi S4. For our car platform however, the intake options are less than ideal - otherwise I would buy one.

An expensive but poor design:

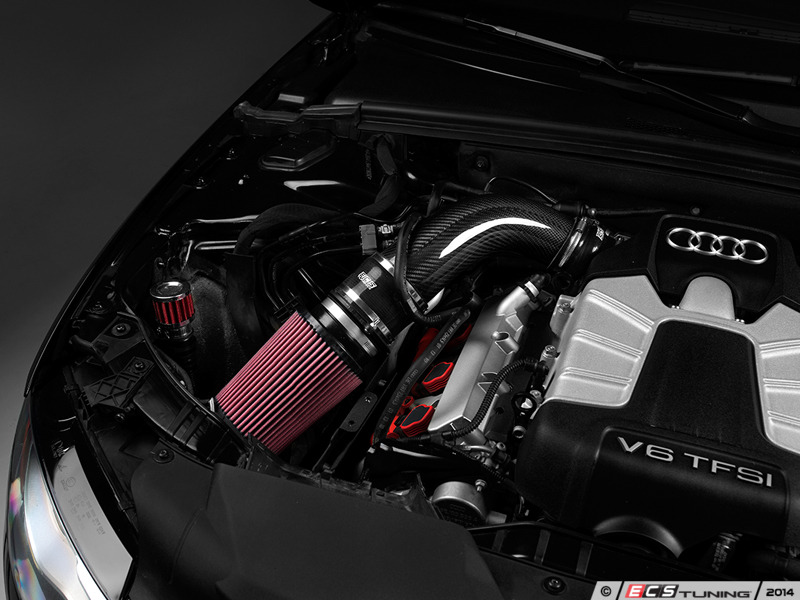

This intake design is ideal, but it isn't for our car and serves as the inspiration for the project:

That said, my idea is to construct a snorkel that could work in conjunction with one of the heat shield only designs as such below:

Now, while I have never done any projects like this - I am pretty handy and learn quickly. I am looking to make a permanent mould, so that it can be replicated... but I have to design the shape first. I'm sure more questions will arise, but the two that I can think of are:

1. What is the best method to create an accurate mould?

2. If I make it a two piece that surrounds the filter, how do I set the threads for the screws to bolt down the lid? (See below for example):

Thank you SO MUCH in advance!!!