Hello

Newbie here

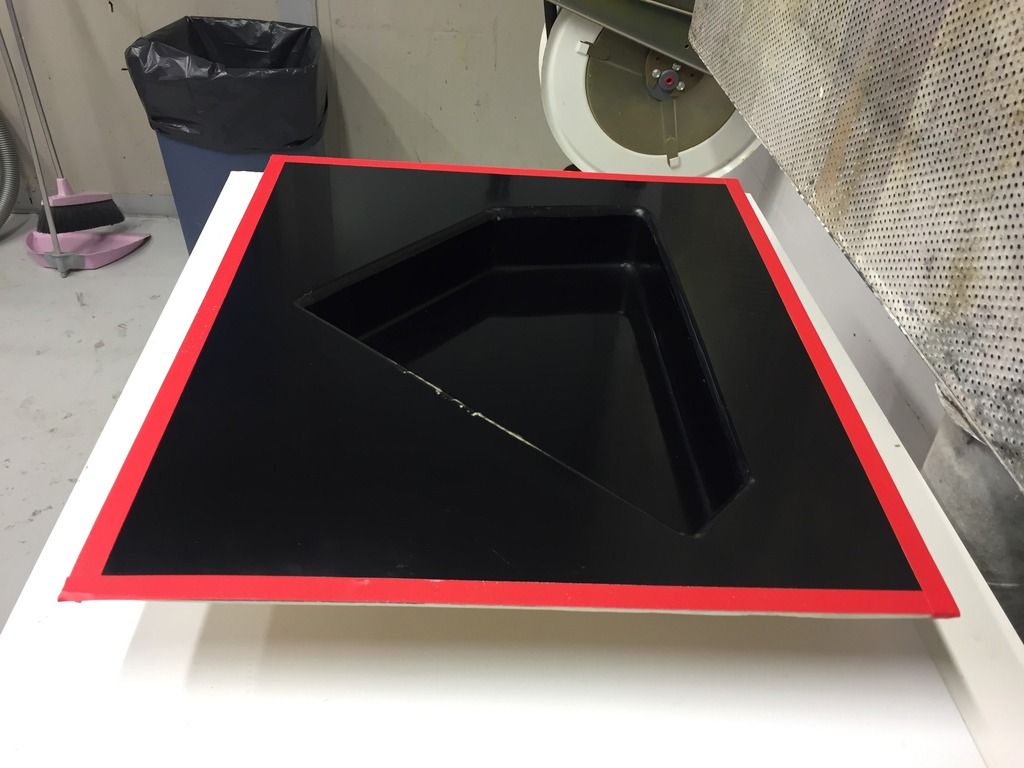

I did two infusions with this mould made with the starter kit, totally failed

The boxed shape corners were not completely pressed in by vacuum, I should have known that. Had too much epoxy in the corners and dry points..

I did try infu-tac, but gave up on it because I mainly messed up and and tore the fabric, messy stuff.. Should I glue the center first and move towards the corners with the glue, or glue in corners only?

Then should I get gelcoat along with infu-tac, as it would leave a cloudy finish? Should I use it post-production or spray in the mold, and does it then work like glue?

Or making my own epoxy tack spray. But am I likely to mess it up? 100:5 epoxy/hardener maybe

So many questions, more to come.

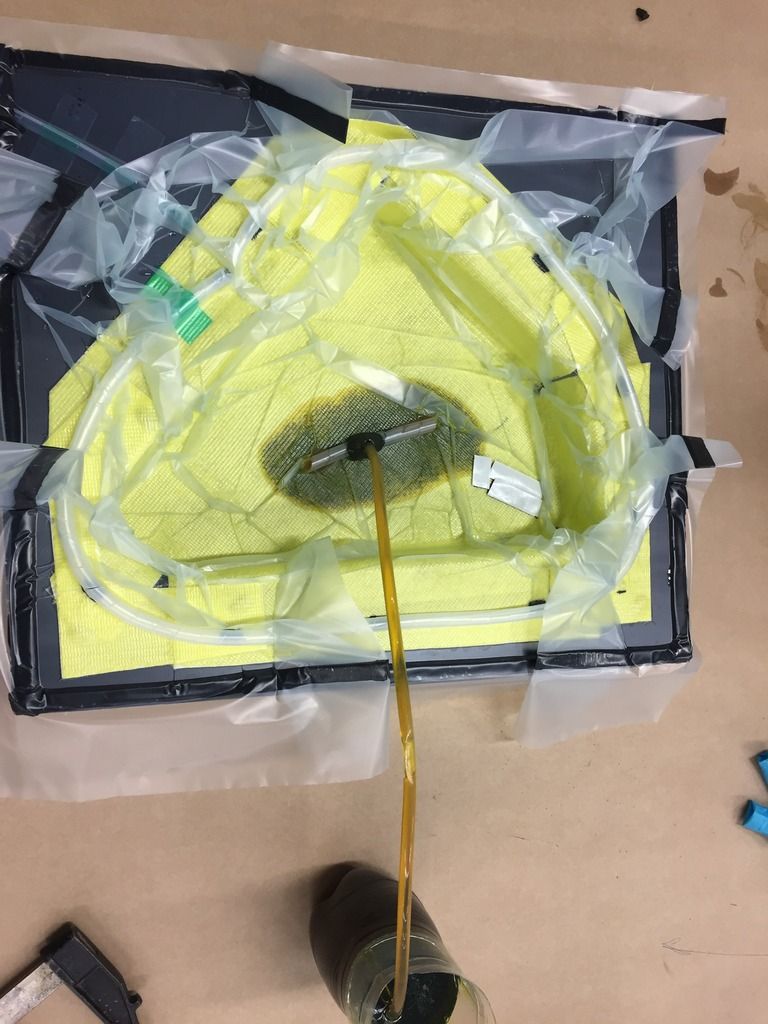

This a good setup for infusion? I used compoflex. Would normal infusion mesh and peel ply be better?

And I had troubles not getting a perfect vacuum. I could not find any leaks but air was getting in from somewhere. There is some damage on the mould caused by removing the pattern, and sanding too much. Think I need to check that the mould is not leaking too.

How should I proceed next time with the infusion. Carefully cutting the fabric in the corners and using glue with other layers also?

Thanks in advance

Ville

edit: pics in google photos, photobucket sucks

https://photos.app.goo.gl/IwY2Fai8QMmB4FV13