Zebra (06/08/2016)

I make carbon fiber stocks which are more complex than your pics. I use compression molding for smaller details.I've been giving a lot more thought to this after hearing Zebra's comment and I'm wondering if compression molding may be the perfect fit? I'm familiar with Vac Cast and have used it before to make mandrels for forming multiple layers of veneer into 3D components. It's also used a lot for doing temporary molds for investment casting wax.

Would it work to make a two part male / female compression mold from my plug using Vac Cast that I'd use tooling gelcoat on? My experience working with Vac Cast for investment casting molds is that it's poured into an aluminum body that has dowel pins through the aluminum that the keep it registered properly.

What are you guys thoughts on this?

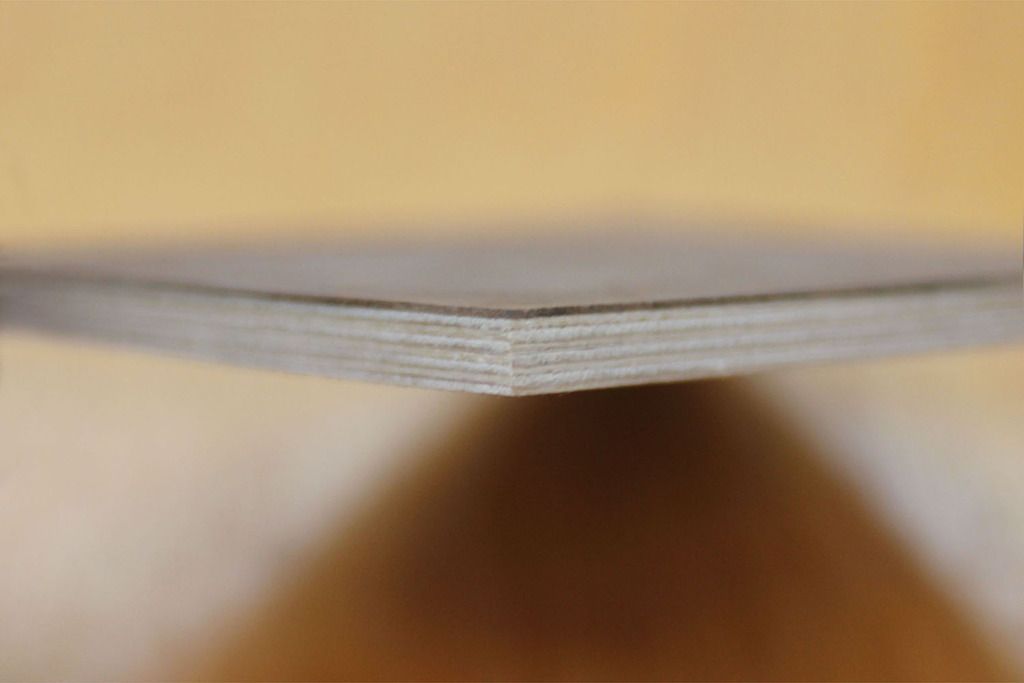

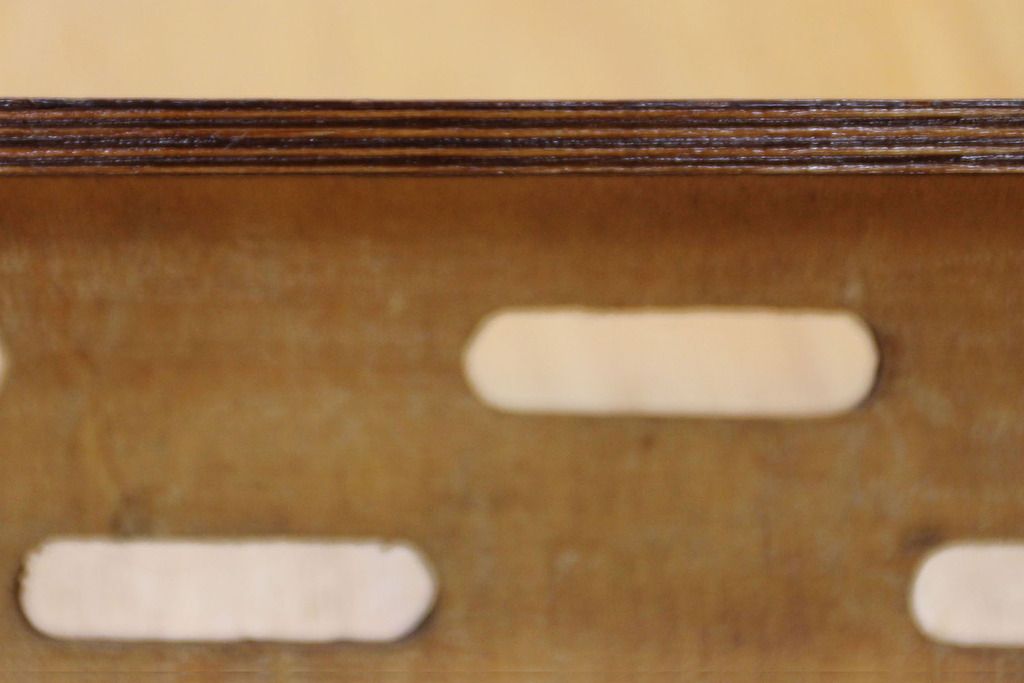

I've attached some pictures how I've used Vac Cast for forming veneers over a mandrel with a vacuum bag for one of the components I’m producing using 7 plys of .023” birch veneer that is 0°/90° cross banded, then has an 8th ply of exotic hardwood for the face veneer using urea-formaldehyde adhesive, that is cured with heat under vacuum.

Once formed, they are put into a vacuum chamber and infused with liquid acrylic then baked to cure the acrylic. This plasticizes the wood making them extremely durable and the only finishing required is with a buffing wheel and polishing compound. Trimming for the outer edges and ends, along with the vents are then machined on a CNC router.

The advantage of using veneers over solid wood is it makes a wood component that has great dimensional stability, with no warp, twist or bow, without splitting or cracking. It also allows you use book matched grain out of a two ply sequence from the flitch, so the right and left side of both halves match identically.