|

Dezer

|

|

|

Group: Forum Members

Posts: 74,

Visits: 1.8K

|

Hello friends,

I was studying making 3D impression moulds and sealing with epoxy resin to make carbon fiber parts in the Wet Layup + Vacuum Bagging or Vacuum infusion process.

Has anyone done any 3D impression mould?

What better material for printing?

The composites will be cured at room temperature.

Thanks!

|

|

|

|

|

scottracing

|

|

|

Group: Forum Members

Posts: 460,

Visits: 5.2K

|

ive done plenty of 3d printed tooling, if you are doing room temp wet lay then you can get away with PLA printed materials but you need to make sure they are properly sealed and released as Epoxy resins stick to them really well. Plus there will be a bit of wet sanding to get them smooth, or you can cover them in flash tape or PTFE release film like Tygaflor

If you are looking into elevated temperatures or autoclave curing then you really need to be looking at better engineered materials, have a look at the graphite am website and there range of ceramic and carbon printed materials.

I would also investigate the use of stratasys ULTEM 1010 and 9085 materials as they are suitable for high temp and autoclave curing.

|

|

|

|

|

Dezer

|

|

|

Group: Forum Members

Posts: 74,

Visits: 1.8K

|

+xive done plenty of 3d printed tooling, if you are doing room temp wet lay then you can get away with PLA printed materials but you need to make sure they are properly sealed and released as Epoxy resins stick to them really well. Plus there will be a bit of wet sanding to get them smooth, or you can cover them in flash tape or PTFE release film like Tygaflor If you are looking into elevated temperatures or autoclave curing then you really need to be looking at better engineered materials, have a look at the graphite am website and there range of ceramic and carbon printed materials. I would also investigate the use of stratasys ULTEM 1010 and 9085 materials as they are suitable for high temp and autoclave curing. Thanks Scottracing, As it will be cured by ambient temperature the conventional materials will supply my needs well. Do you have any pictures of a 3D printed mould ? Thankful.

|

|

|

|

|

Lester Populaire

|

|

|

Group: Forum Members

Posts: 311,

Visits: 13K

|

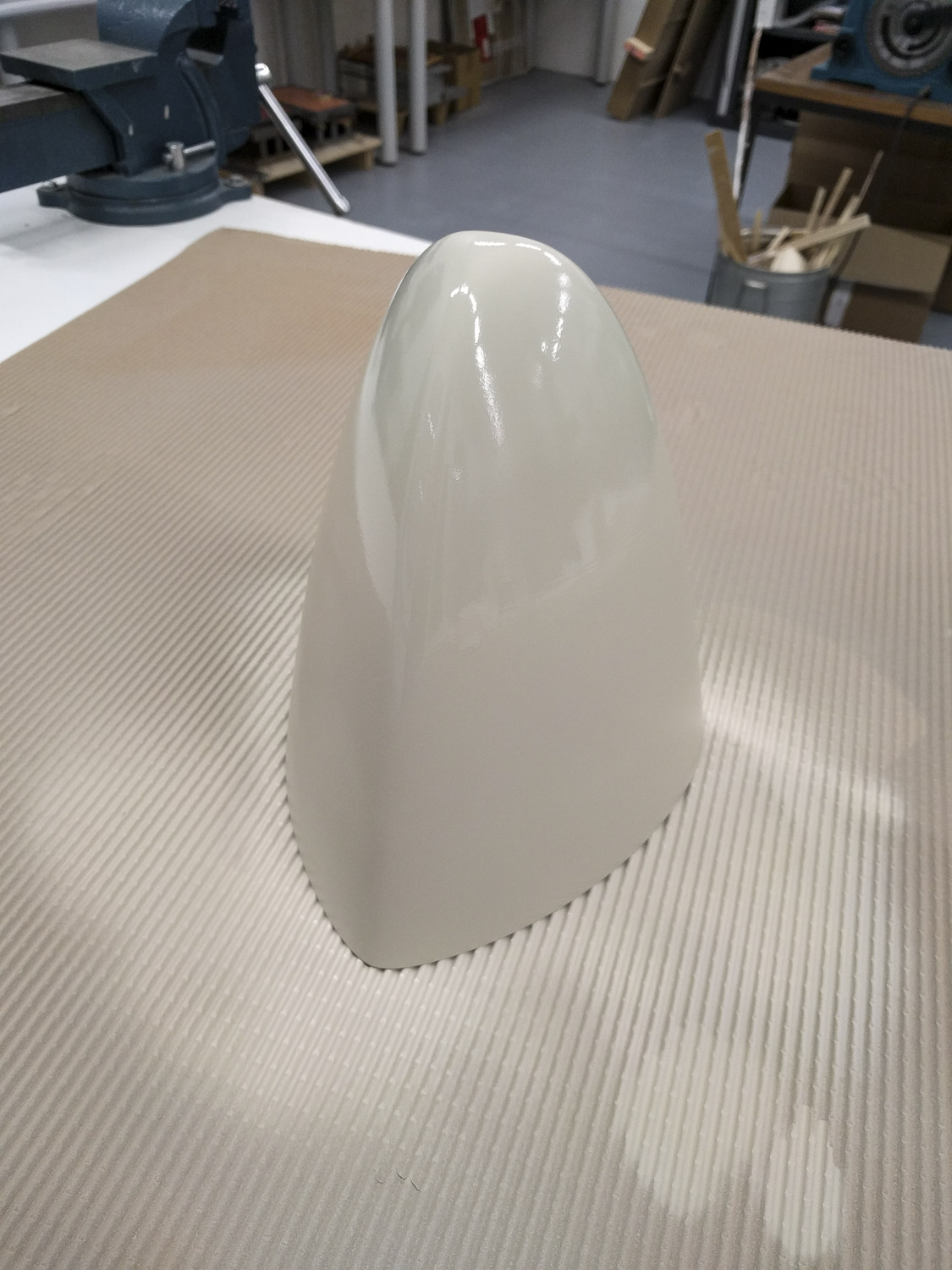

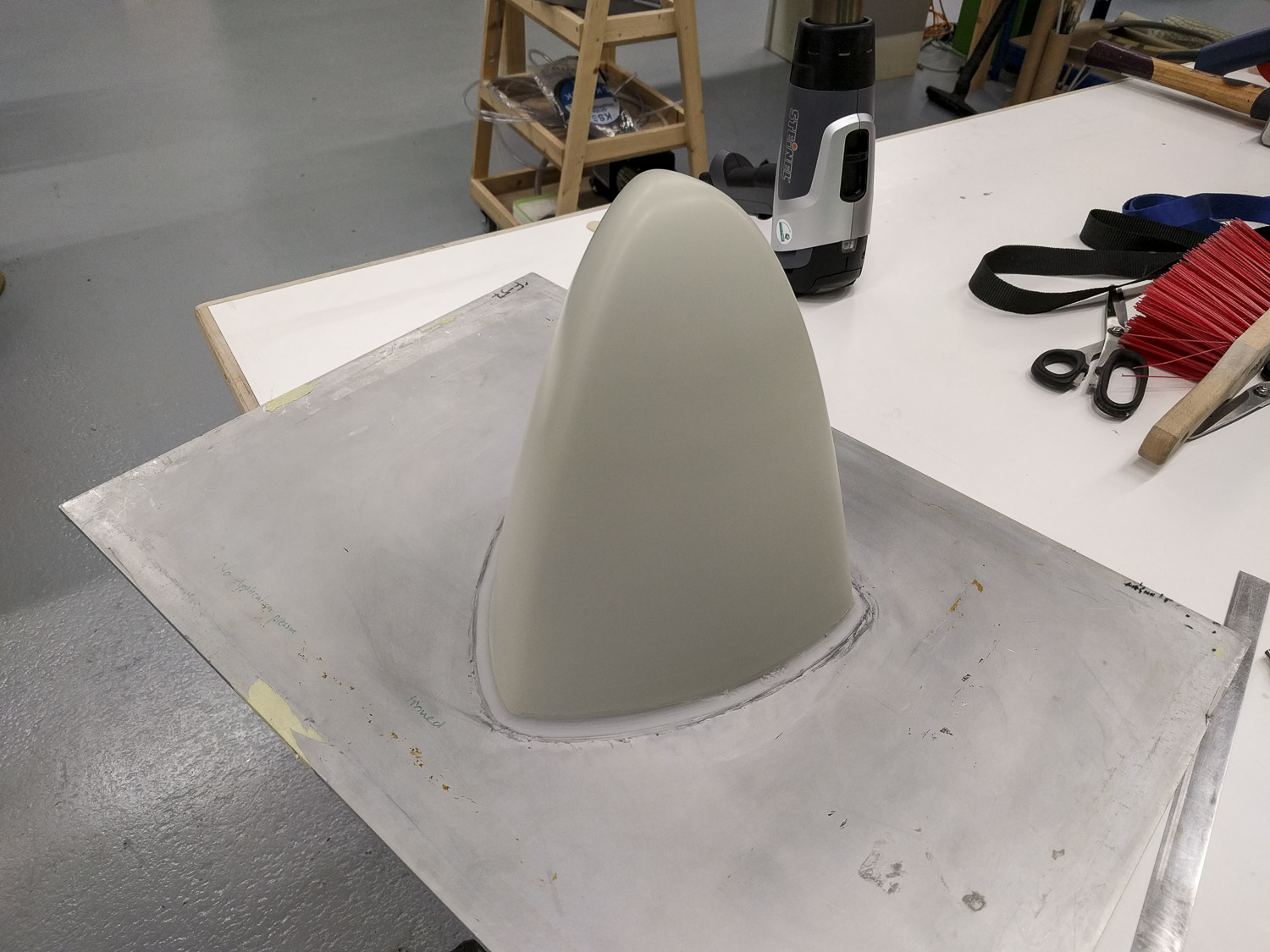

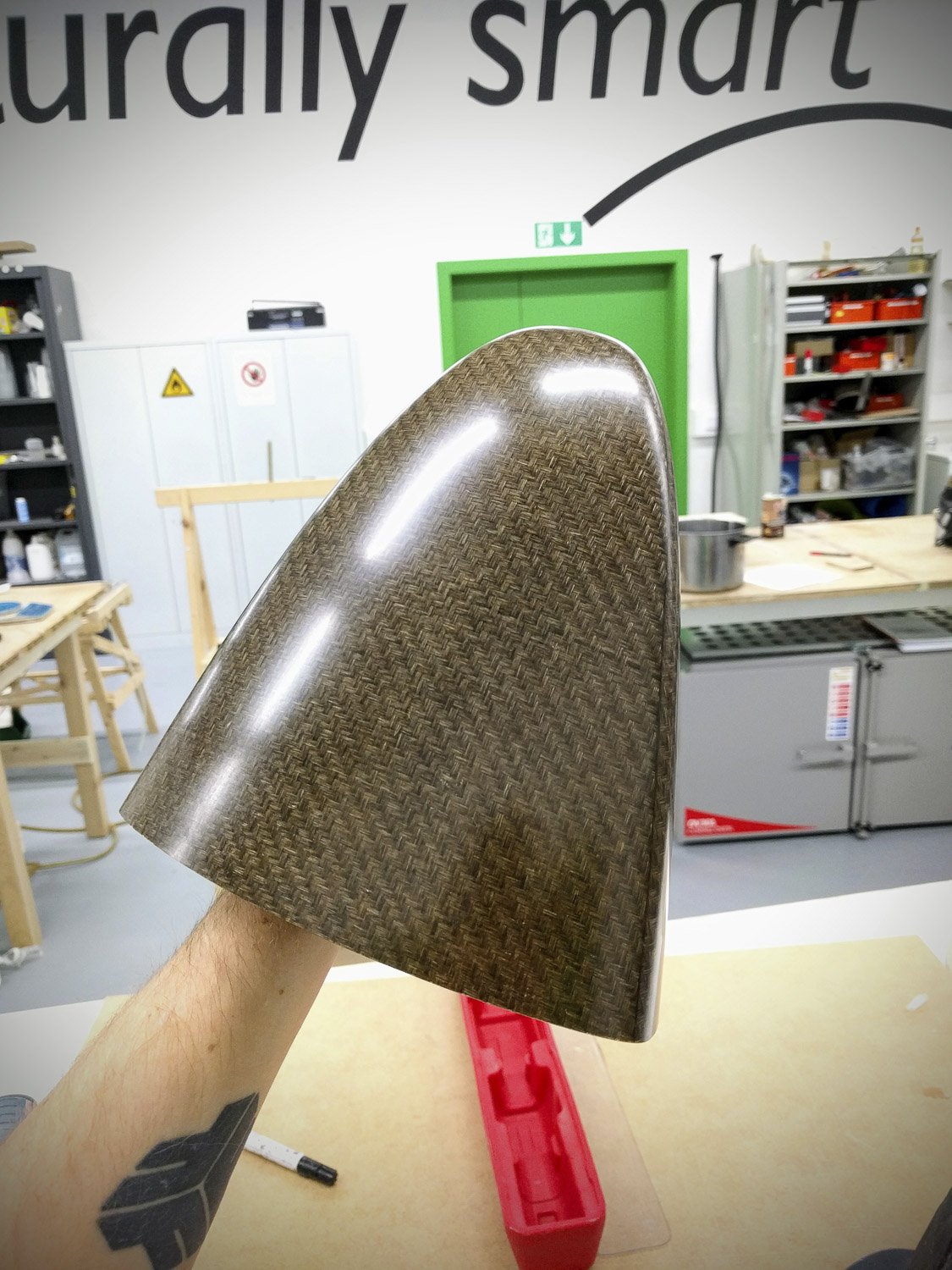

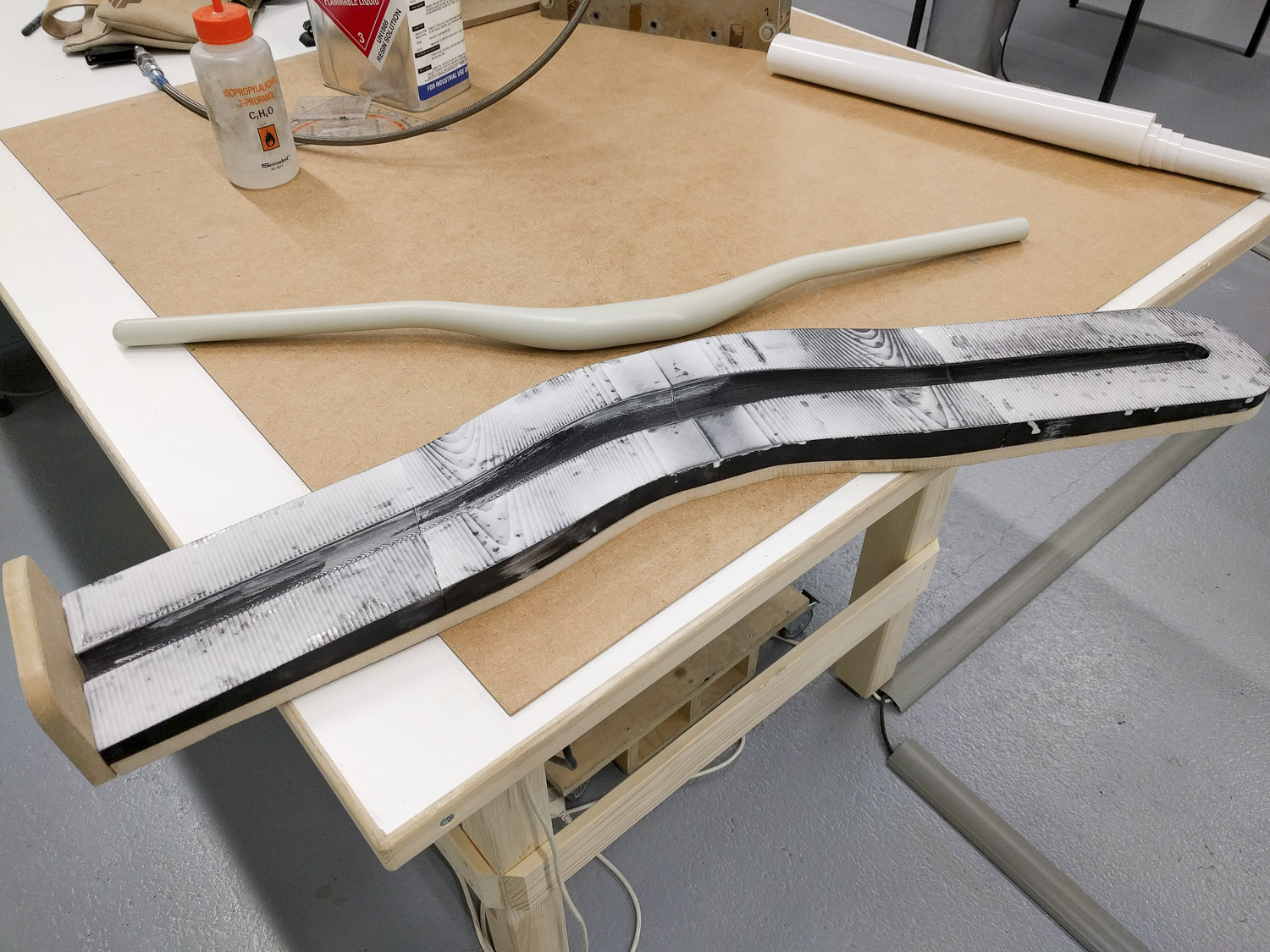

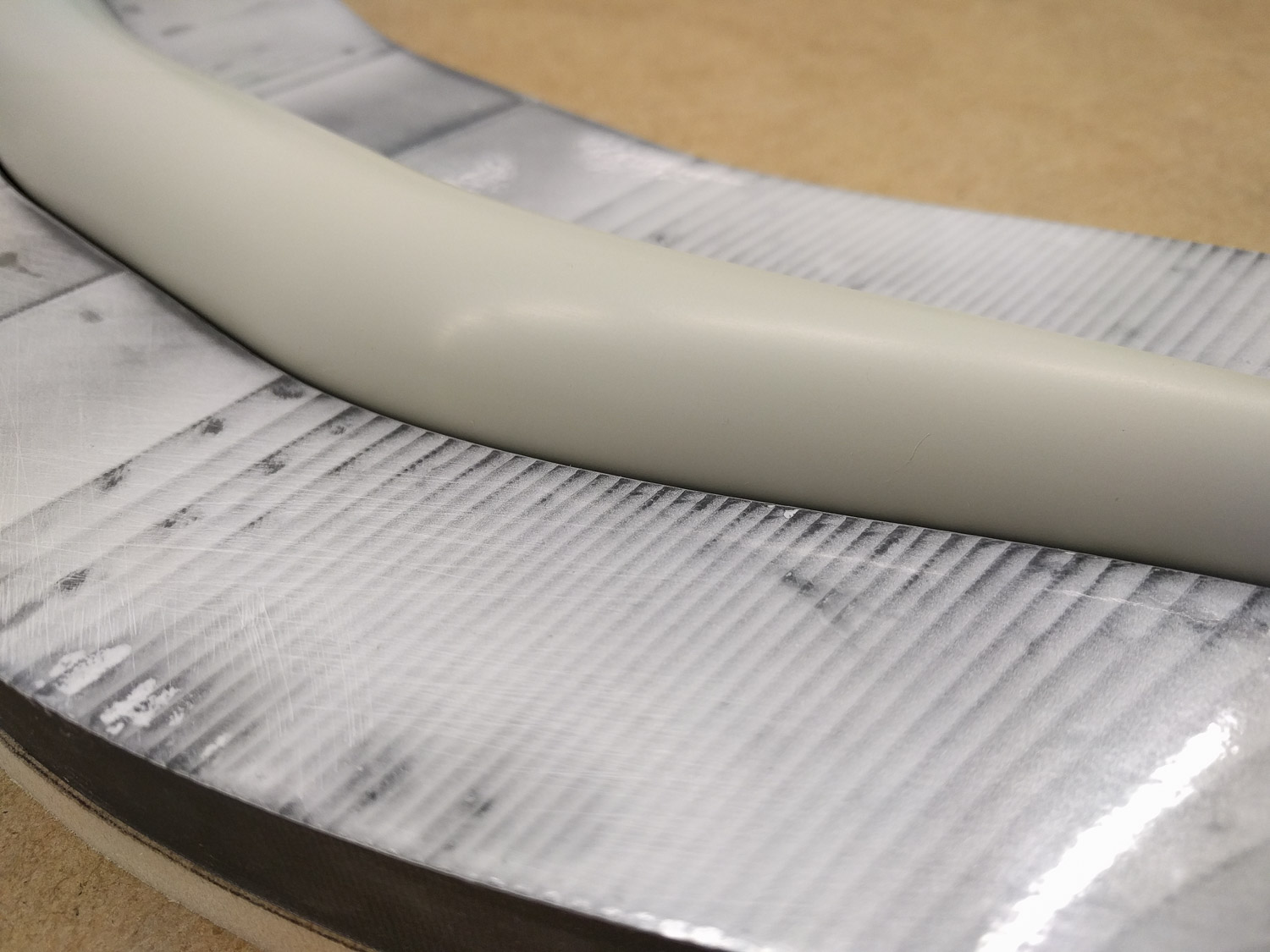

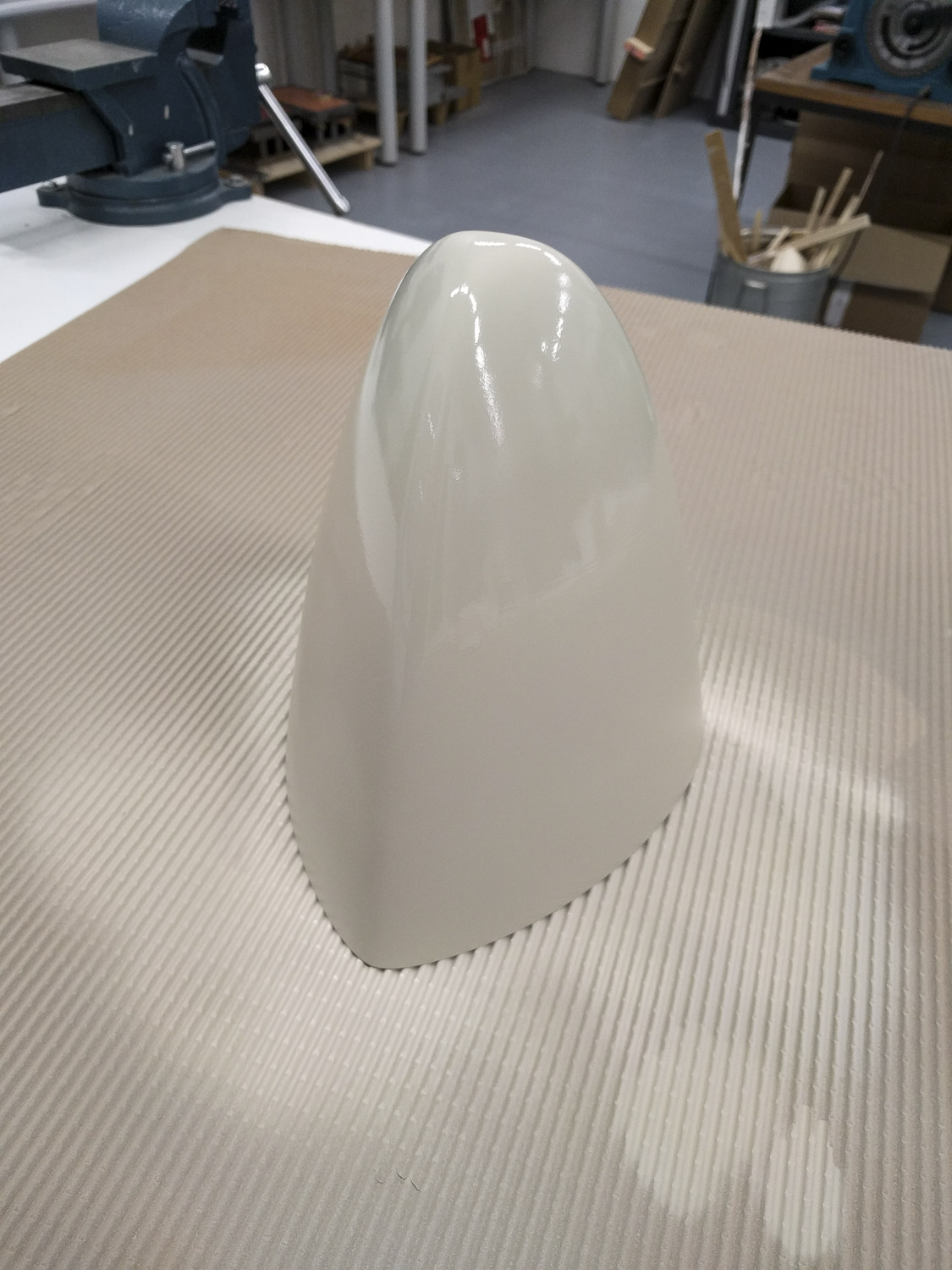

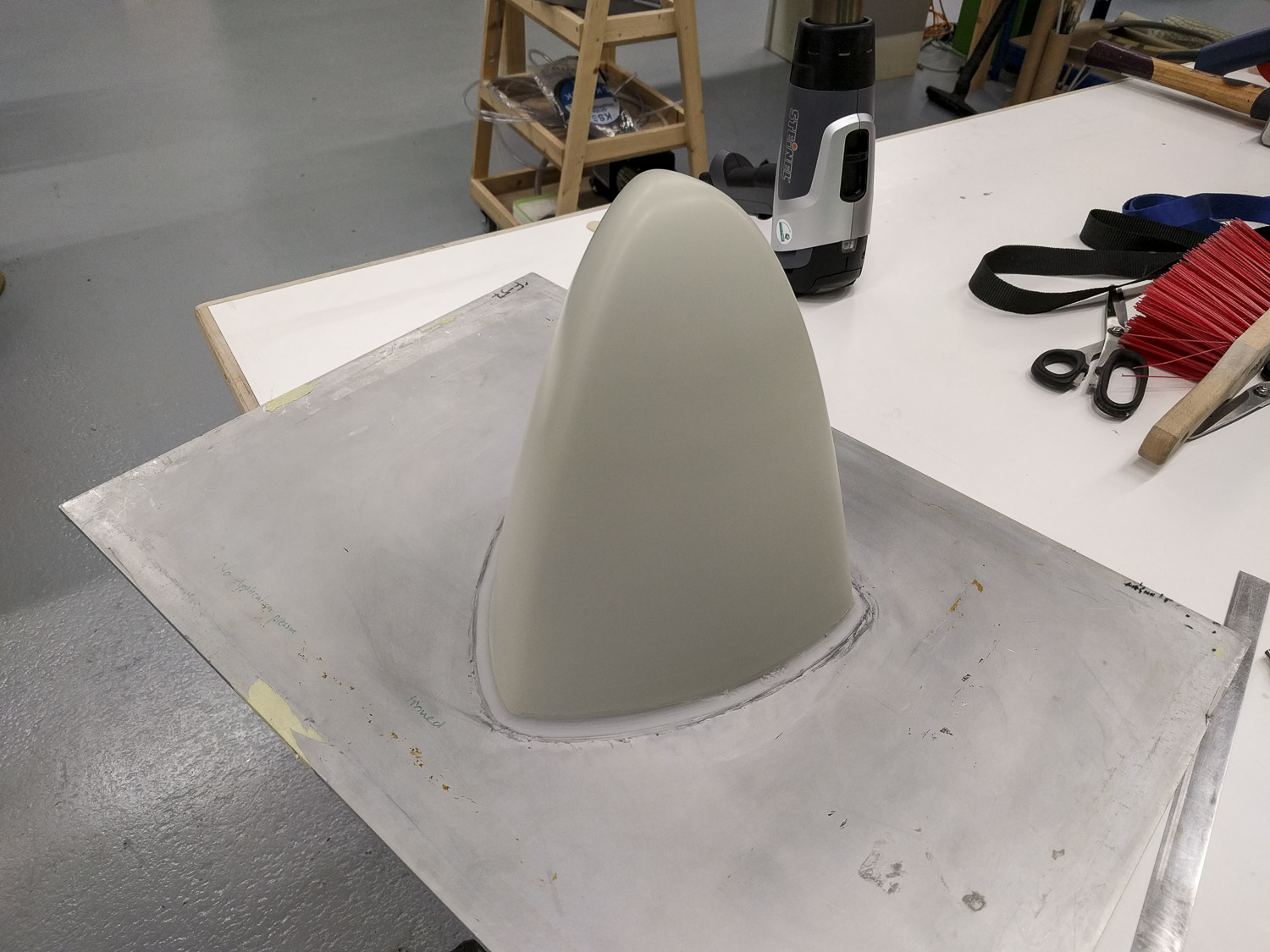

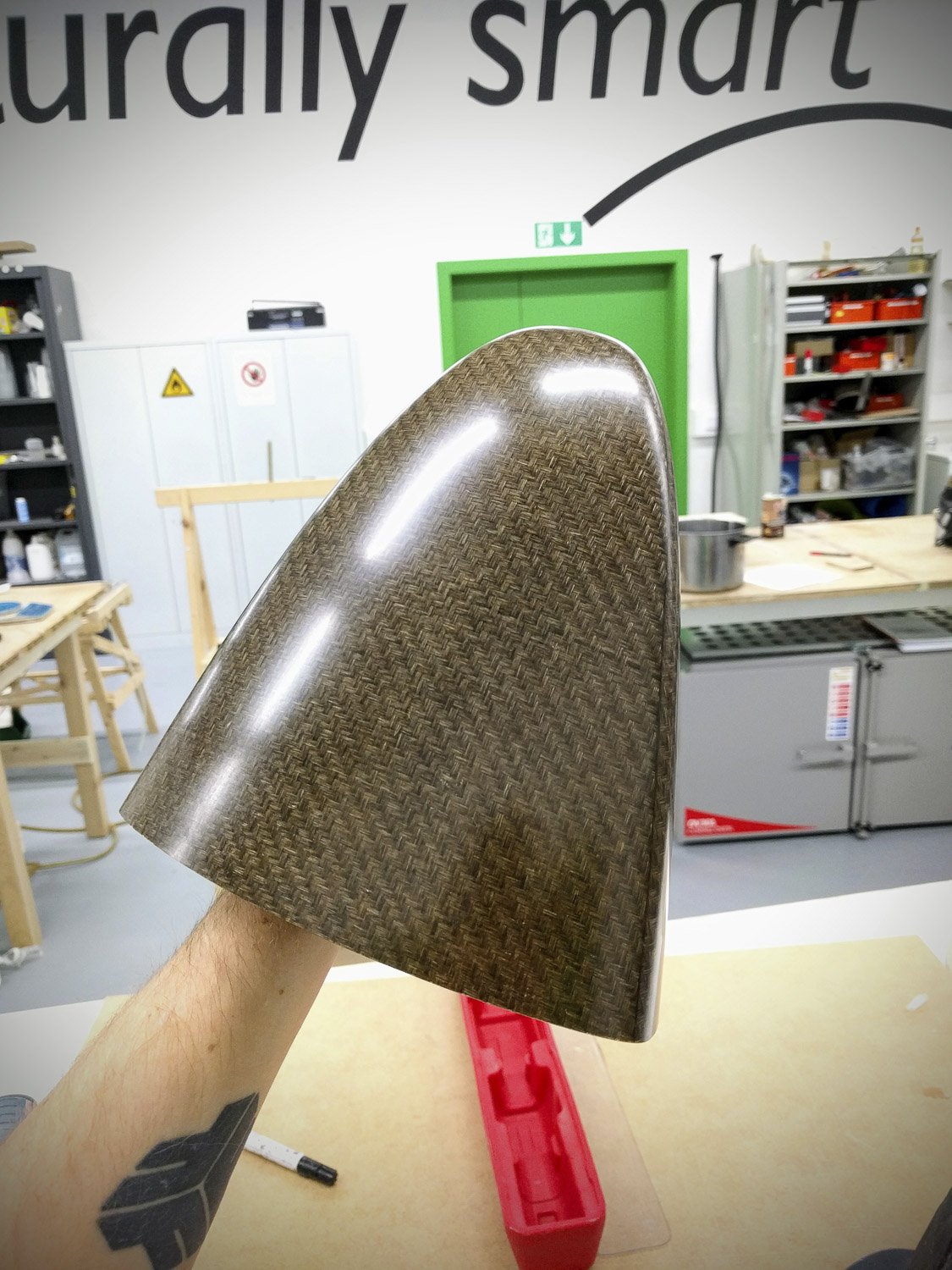

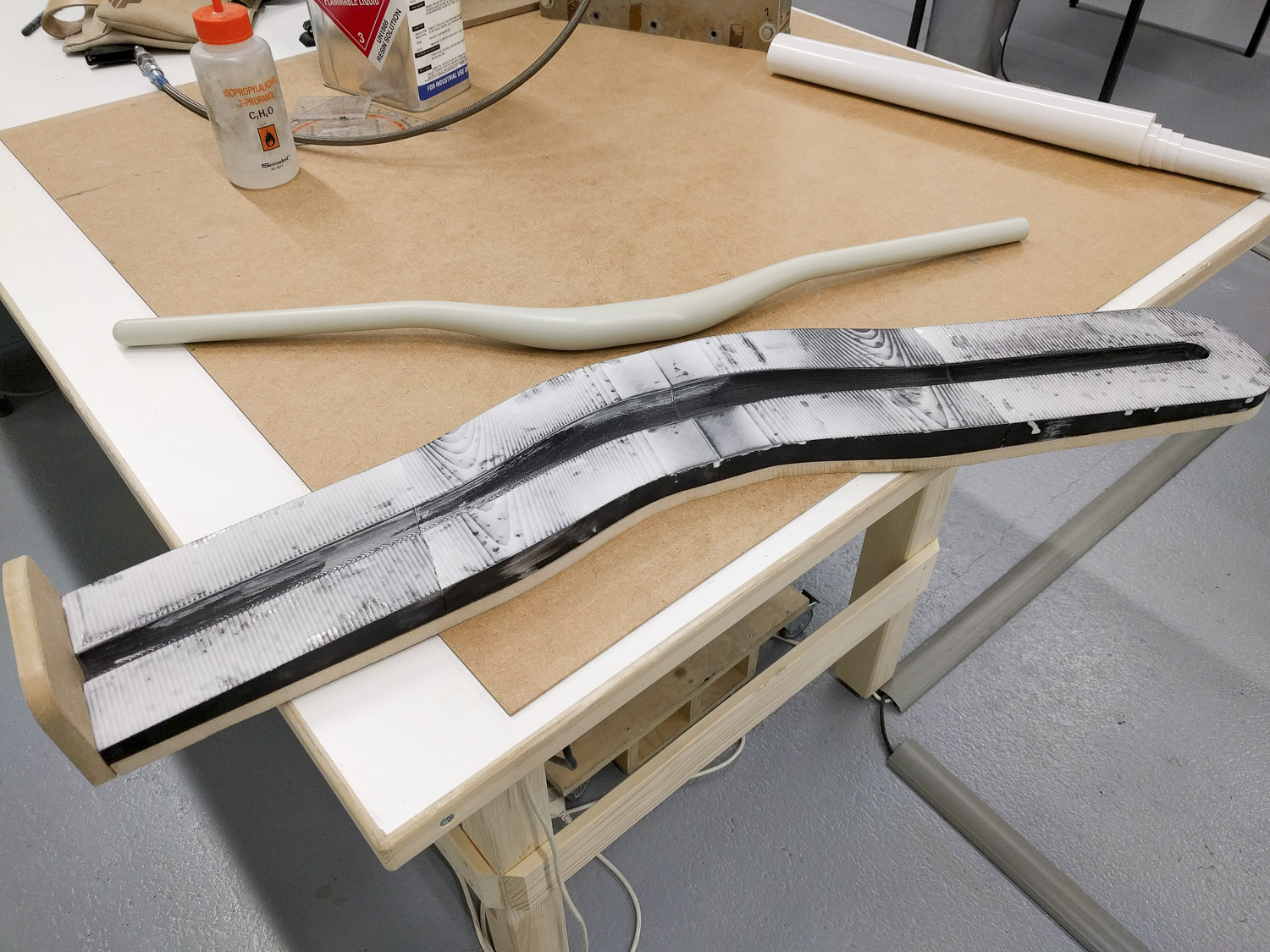

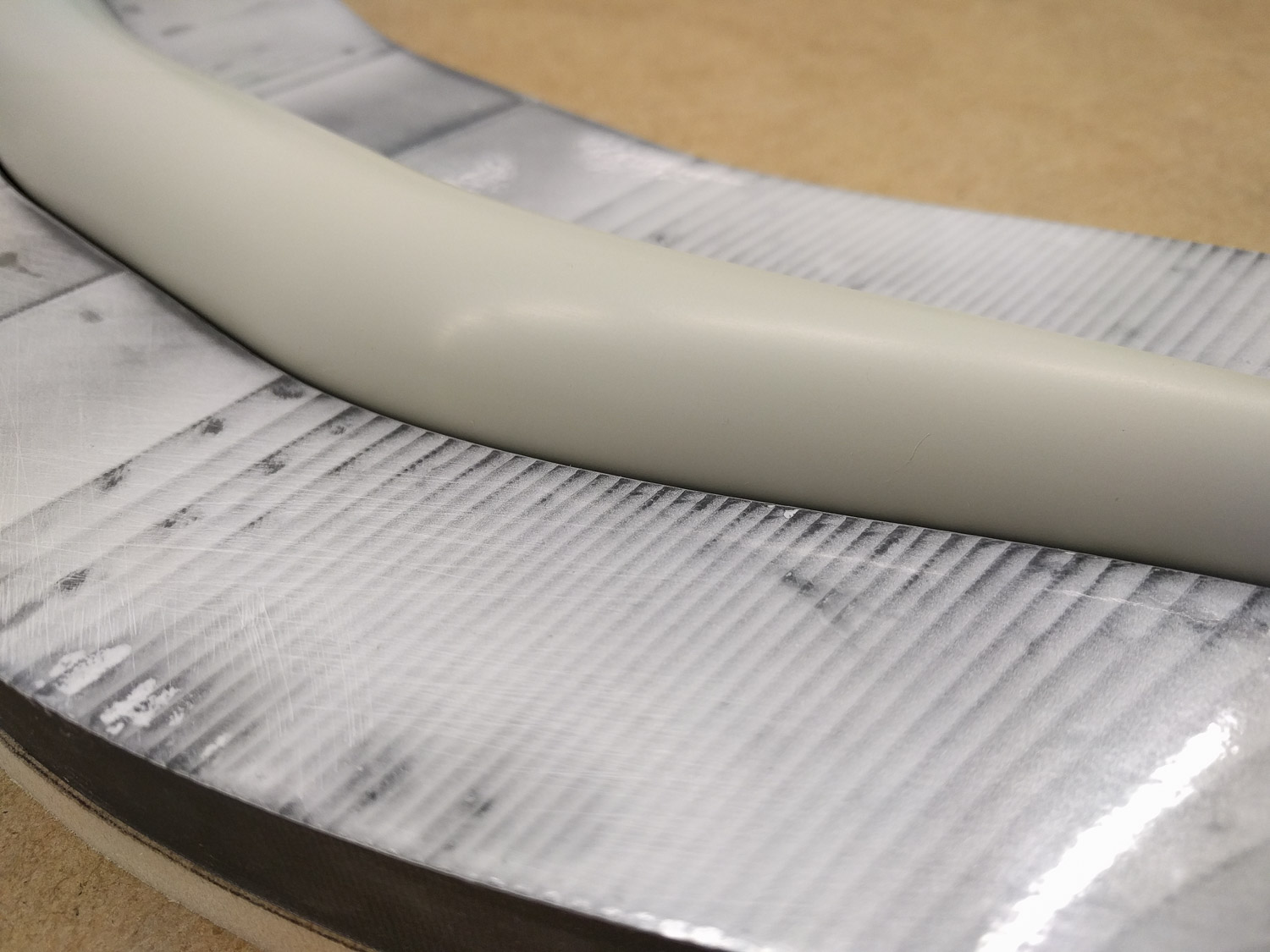

I just have some pictures of printed positive moulds on hand and thought i would share them. printed in PLA on a Prusa printer.  second layer of spray filler  sanded to 800 grid  with tooling gel coat  finished mould (made with vacuum infusion) and the first part  first part close up. Finish straight out of the mould.  Another project with the bar and the lower mould have printed to get an accurate split line exactly in the center of the bar.  this is how the first mould have is made, then the lower part is removed and a composite mould is made instead.  And a close up of the finish. getting a really smooth finish and decent dimensional accuracy is really easy even with a relatively big layer height. I hope this helps. Cheers, Reto

|

|

|

|

|

Dezer

|

|

|

Group: Forum Members

Posts: 74,

Visits: 1.8K

|

+xI just have some pictures of printed positive moulds on hand and thought i would share them. printed in PLA on a Prusa printer.  second layer of spray filler  sanded to 800 grid  with tooling gel coat  finished mould (made with vacuum infusion) and the first part  first part close up. Finish straight out of the mould.  Another project with the bar and the lower mould have printed to get an accurate split line exactly in the center of the bar.  this is how the first mould have is made, then the lower part is removed and a composite mould is made instead.  And a close up of the finish. getting a really smooth finish and decent dimensional accuracy is really easy even with a relatively big layer height. I hope this helps. Cheers, Reto This will help me a lot, for sure! Many thanks friend!

|

|

|

|

|

scottracing

|

|

|

Group: Forum Members

Posts: 460,

Visits: 5.2K

|

what layer height did you use on the PLA print? And did you sand it prior to the first coat of primer?

The finished part looks brilliant, is that a flax/hemp material you made the part from?

|

|

|

|

|

Lester Populaire

|

|

|

Group: Forum Members

Posts: 311,

Visits: 13K

|

+xwhat layer height did you use on the PLA print? And did you sand it prior to the first coat of primer? The finished part looks brilliant, is that a flax/hemp material you made the part from? I usually print with a Layer height of 0.15 to 0.2mm and give it a light sand to get rid of small bumps where a new layer started and any things like that. Then usually two coats of heavy filler and one coat of finishing filler with wet sanding is enough to get a good finish. The part is made from Bcomp's ampliTex 5040 fabric.

|

|

|

|

|

Warren (Staff)

|

|

|

Group: Administrators

Posts: 2.5K,

Visits: 8.5K

|

Nice to see some natural fibres being used. How does it compare stiffness wise? Most natural fibres seem very poor compared to more advanced composite fibres - albeit usually the environmental credentials or different looks are usually more of a priority.

Warren Penalver

Easy Composites / Carbon Mods - Technical Support Assistant

|

|

|

|

|

scottracing

|

|

|

Group: Forum Members

Posts: 460,

Visits: 5.2K

|

looks really good,we have been trialling some of the bcomp material at work and finding its not as good as it says on the tin,but i think for non structural applications like bodywork it should be good,i especially like the power ribs such a great and simple idea

|

|

|

|

|

KOSTAS

|

|

|

Group: Forum Members

Posts: 30,

Visits: 244

|

+x+xwhat layer height did you use on the PLA print? And did you sand it prior to the first coat of primer? The finished part looks brilliant, is that a flax/hemp material you made the part from? I usually print with a Layer height of 0.15 to 0.2mm and give it a light sand to get rid of small bumps where a new layer started and any things like that. Then usually two coats of heavy filler and one coat of finishing filler with wet sanding is enough to get a good finish. The part is made from Bcomp's ampliTex 5040 fabric. 0.15 layer height !!!! How many hours did it take you to print this bar mold ?

|

|

|

|