Thought I'd have a go at making a lightweight hardtop. My aim wasn't ultimate lightness but the lightest I could go without compromising OEM type operation. This required standard fittings and format. Having a lotus hardtops one to refer to was useful. Having looked closely at it I figured a cored carbon lay-up was best. I also thought some weight could be shed by cutting the inner part down quite a bit. Anyways, here's a few pics of the adventure....

Mould for the outer cleaned and polished:

Outer skin of the outer going in. This is two layers of 200g carbon layed at 45 degrees to each other.

Bag on:

Once cured its time for bonding in the foam core. I used a 3mm pvc foam with vacuum to help conform it to the shape.

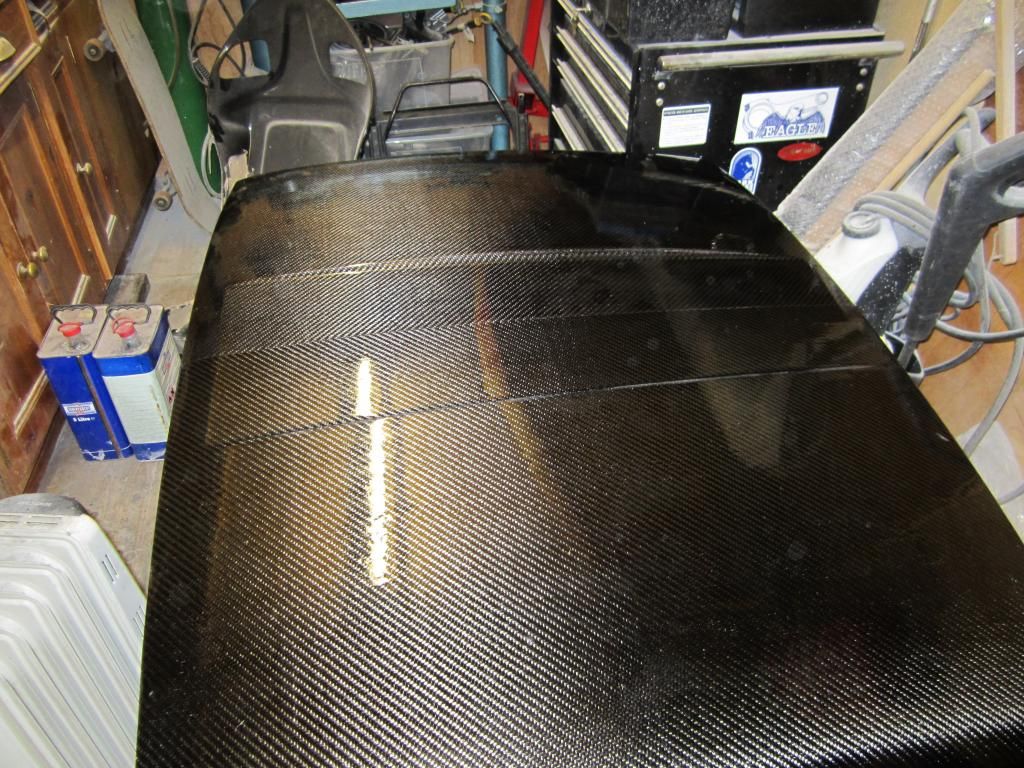

Once that was cured the inner skin of the outer was layed up. Again this was 2x200g carbon at 45 degrees. Clearly I was a little liberal with the resin!

This gave an outer (once trimmed) that weighed something like 1.8kg. It was surprisingly rigid and would suit bonding on for a track car 'as is'. This wasn't may aim though.

With the outer done it was time for an inner. Lotus hardtops were kind enough to make me an inner with fittings (top chaps!). Once it arrived it got dremmeled! The outer was put back in its mould, it was vinyl covered and the modified inner was layed in.

This was moulded and an inner was made to the same lay-up as the outer. Where the fittings are I layed in some additional carbon and some aluminium load spreader plates. Where the plates were, these replaced the foam core.

Given my 'spray booth' is a little wet and windy I've started lacquering it in the shed. I'll brush a couple of coats on then flat that off and spray the final coat. Couple of mid-way pics.

Just about done now, just waiting on a nice day for the final spray. Gloss outside, matt inside. Final weight is 3.4 kg

For some reason I'm unable to view posts beyond page one (some weird win8 setting I suspect) so if a mod wants to move this to the project showroom that'd be ace.