This is a weight sifting exercise for a friend who is in a marching band.

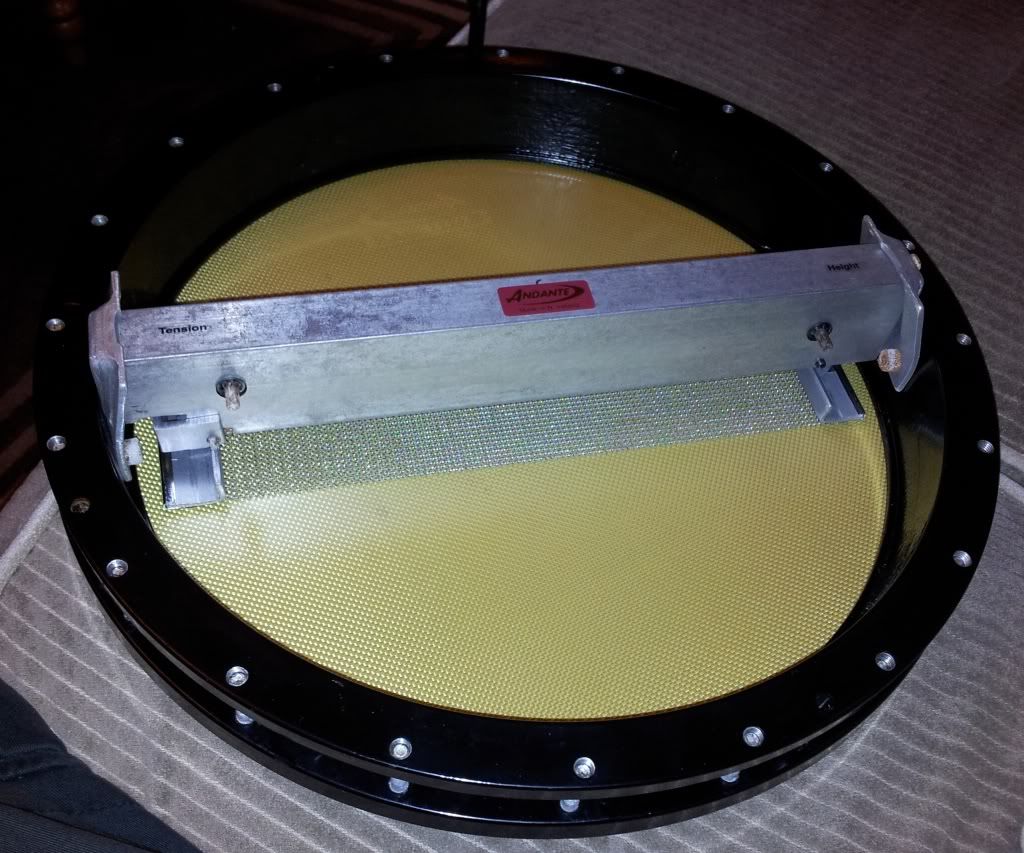

He and the band carry around drums like these:

The drum weighs 7kg which doesnt sound that much but it is when you consider its carried all day.

Most of the weight is in the hoops at the top and bottom which are made of solid metal.

The aim is to see if they can be made from a composite material and still be strong enough.

Now these are the top rings close up:

In effect it is two rings with the drum skin between them. Buy tightening the two together with the allen head screws, you tension the skin. In effect the bottom ring is pressed on the skin while the skin ring is pulled down by the top ring as it is tightened.

the snare unit is not an issue, its already a hollow alloy box section so not worth the effort for little gain.

Now the shape isnt hard to make so i know i can easily save weight if you went for a simple copy out of carbon. However there are both crush forces acting on the carbon (against the drum skin) and a lot of tension around both edges of the rings as they are tightened together.

That is an unusual combination on carbon.

Already im thinking you will need a laser cut metal ring top and bottom to spread the load and to take the bolts and thread.

Any ideas on if carbon can take the crush forces needed for this kind of application??