By Neiluj - 7/26/2014 9:47:25 PM

Hi everyone,

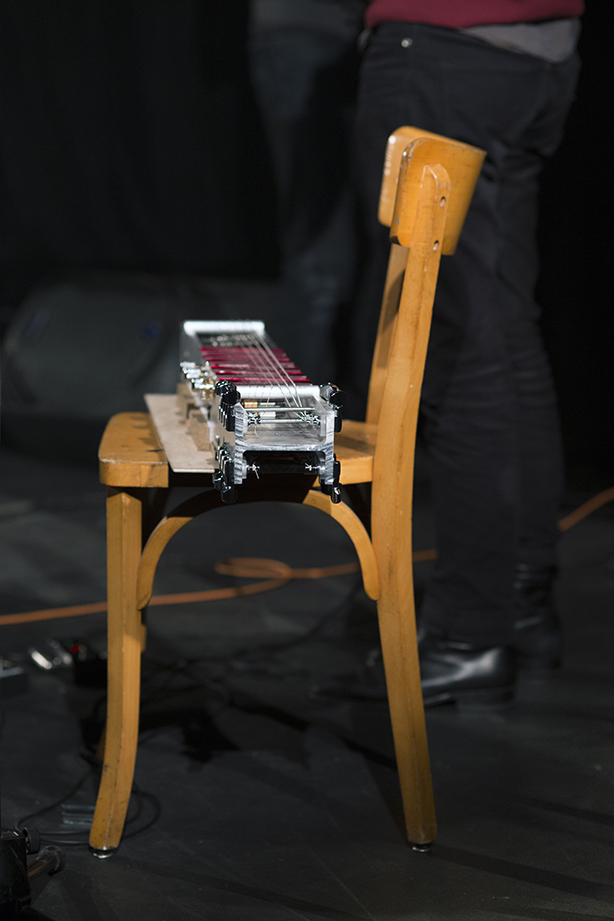

I would like to build a carbon I beam (IPN). Around 1 meter long, 12 cm for the center part and 8 cm for the parallel parts. I would need it to be quite stiff and with a thickness around 3mm at least. Does anyone has any idea of how to do this ? To be honest my project is to build a lap steel guitar, similar to this one (already made by myself, into aluminum)   My questions are : Will I find a rather easy way of making a I beam, or is it more simple to just do 2 U beams that I glue together ? What would be the down points of making two you beams instead of a I beam ? Can I avoid the backing part ? I saw tutorials on the internet where the guy puts his composites in the oven and some where he does not and I haven't yet figured out what the true difference is ? (the video clips i saw about cello and guitars were actually baking their parts). Can I avoid the infusion part (although I find it very cool) ? In other words what would be the down points of doing a simple method like this one : |

By brainfart - 7/28/2014 6:33:57 PM

I think f1rob pretty much means the same, maybe this:

XXXXXXXXXXXXX

XXXXXX XXXXXX

X X

X X

XXXXXX XXXXXX

XXXXXXXXXXXXX

2 U things glued together and then laminated on the outside and compressed with some plates.

> About the DIY oven, I'll start investigate but if you have any pictures, links or tips...

Thanks for reminding me, I have an oven project going on right now, might post a description as soon as it is presentable.

It involves an Arduino and a Raspberry Pi which logs temperature data, acts as a web server and displays temperature curves and controls the whole oven (PID, temperature ramp up and down) over the internet or your local network/WLAN with your smartphone, tablet computer, TV set, labtop etc. Cost for the whole controller will be around 100-150€, plus whatever oven is being used (*cough* ... old broken fridge or freezer *cough*), accuracy hopefully 1°C or better.

Ultimately I want to control an autoclave with it, but that's yet another project.

A real oven isn't necessary, you can improvise this. As I said, cardboard box and hairdryer will work, or a styrofoam box and a few lightbulbs, part wrapped in dark plastic and left in the sun, car parked in the sun in summer... be creative.

> i may be able to ask in the kitchen of my work. Do you know if there is any danger of curing carbon in a protection

> bag and cooking a dish afterwards ?

I wouldn't do it. Not only because of the resin vapours (which might be not that dangerous depending on what resin is used, others might disagree), but since you are using somebody else's oven and other people eating food prepared in it... better not.

Another reason is temperature accuracy. Kitchen ovens tend to be rather inaccurate and the temperature oscillates wildly, like +/-10°C. If you want to tighten them up you need to modify them.

> What about the vacuum hose, will it have to be squeezed between the door and the frame ?

No. You can cure the part for a day or two at room temperature and then place it into the oven, when the resin is already hard and it doesn't require any vacuum anymore.

|

|