Hopefully next year i will be stripping out my car and fitting a weld in cage as part of a weight loss programme.

once the cage is in, i want to get drastic on cutting out metal and saving weight on the non-structural elements of the shell.

Obviously i will replace as many cosmetic body panels with carbon ones - plenty to save there.

However my slightly insane plans include replacing some of the now redundant monococque.

In a handling sense, the roll cage will be far stiffer than the original bodywork, so ive nothing to loose there. In a safety sense, the roll cage alone is strong enough as defined by FIA/MSA standards.

So all the bodywork needs to do is keep the weather out.

In an ideal world, i would cut off all the metal work above the suspension top mounts and secure the cosmetic panels to the cage. However you still need a form of support framework for the panels, roof and boot to stop the carbon panels flexing too much.

So what i intend to do is cut out the steel framework within the upper part of the car and remould it in carbon kevlar. A major panel is the quarter framework spanning the B and C pillars and roof line.

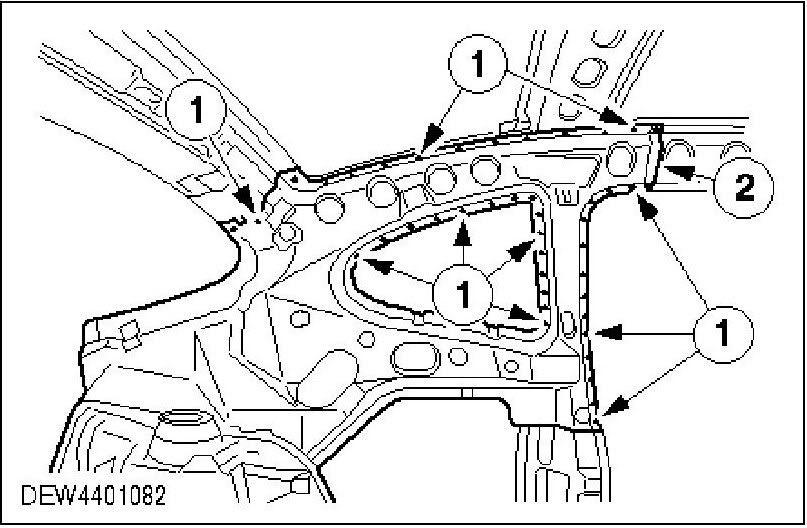

from the inside:

Outside:

As you can see it is a double skinned inner frame. It is made of approx 1mm thick pressed steel.

Relatively easy shape to mould and i reckon considerable weight savings to be had over steel. Some of my mates reckon the car would crumble, but im not convinced. The suspension points are all tied into the roll cage so the basic floor pan monococque has a steel frame supporting it of the roll cage which is significantly stiffer than oem pressed steel so IMO no structural weakness compared to a standard car if those inner panels are replaced.

Plus of course a carbon/kevlar replacement will be stiff in itself in handling terms. Sure in heavy roll over type crashes it fails differently and more catastrophicly compared to pressed steel, but thats what the roll cage is for.

I intend to do the same to the roof rails above boot lid and each door as well as the roof central brace. I intend to leave the A pillar and windscreen bracing in steel as welded to the cage they will be useful for extra strength.

If i can get extra spaceframing tubing welded in along the sills and gearbox tunnel and across the floors, i may even cut out the steel floorpans each side of the car and replace with carbon kevlar too.

Possible or just plain insanity?? Some of my firends just think im insane.